LEVULINATE TECHNOLOGIES VERSATILITY

GFBiochemicals is a global innovator dedicated to creating and manufacturing safe, sustainable, and high-performance alternatives to petrochemical ingredients. Backed by over a decade of research and nearly 200 patents, the company has unlocked the potential of the levulinate platform and its derivatives to develop versatile, next-generation ingredients.

LEVULINATE TECHNOLOGIES VERSATILITY

GFBiochemicals is a global innovator dedicated to creating and manufacturing safe, sustainable, and high-performance alternatives to petrochemical ingredients. Backed by over a decade of research and nearly 200+ patents, the company has unlocked the potential of the levulinate platform and its

With our breakthrough technology: RE:CHEMISTRY, we are redefining the future of industrial chemistry, empowering businesses to produce everyday products that are clean, safe, and sustainable.

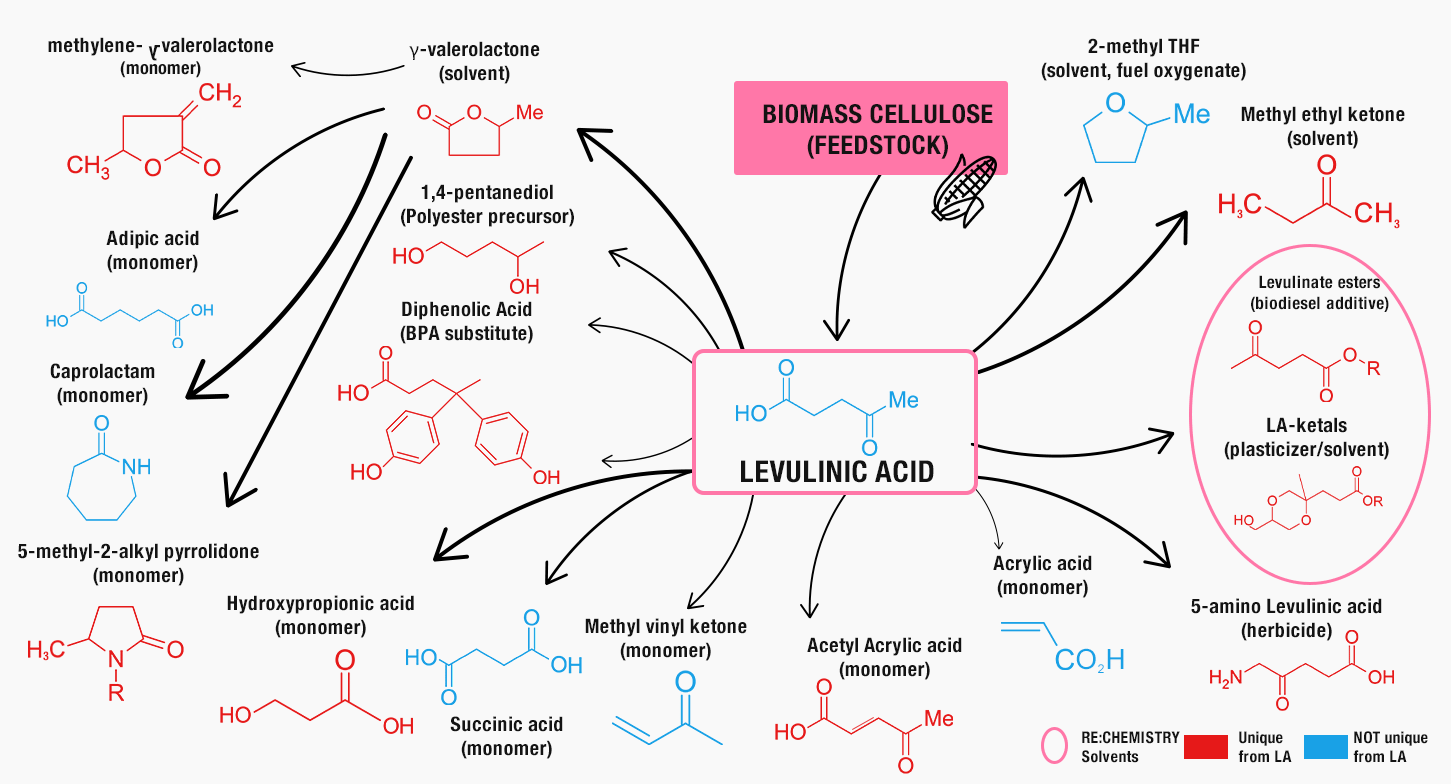

LEVULINATE ACID ESTERS & KETALS PATHWAY

STRONG IP PROTECTION

PLANT-BASED UNIQUE PROPRIETARY TECHNOLOGY

Biomass conversion demonstrated at industrial scale

Strong IP protection

Levulinate Technologies

Conversion into levulinate technologies & its derivatives Strong IP protection on solvents, polyols and plasticizers

Bio-solvents produced to date

High Solvency Power

RE:CHEMISTRY

THE BREAKTHROUGH TECHNOLOGY THAT UNLOCKS HIGH-PERFORMING PLANT-BASED INGREDIENTS FOR EVERYDAY PRODUCTS THAT ARE SAFE AND SUSTAINABLE

SIGNIFICANT CARBON REDUCTION USING

SAFE & SUSTAINABLE SOLUTIONS

GHG impact vs Incumbents

Plant-based Carbon Content

Compelling carbon footprint compared to petrochemical solvents:

Propylene Glycol – 12 times the CO2 emissions of RC SOLVE100

Tetrahydrofuran – 16.5 times the CO2 emissions of RC SOLVE100

Biogenic carbon is absorbed and stored by the flora on our planet as a natural consequence of its life cycle.

HSE PROFILE

Levulinic acid is a platform molecule made from Agro-waste, with a left hand and a right hand functionality, which each can be independently transformed to different functionalities and therefore to a wealth of molecules targeting different applications.

It’s a major breakthrough in the chemistry world !